The Conference of Northern California Handweavers was last weekend in Modesto, and at the conference I chatted with Sara Lamb and Mollie Freeman about how I've been feeling disconnected from the Sacramento weaving community since I moved to Sacramento because the guild here meets during the week while I'm at work. When I lived in the Bay Area, I joined the Loom & Shuttle Guild, which meets on Saturdays, and I've developed these wonderful friendships and have gotten a lot from the members who were more than willing to mentor & guide me along when I was weaving in "butt-ugly colors" (quote is from Penny Peters). I'm still a member of Loom & Shuttle and think that perhaps I should make more of an effort to get down to their meetings. Sara Lamb has interesting ongoing statements on her blog about the future of weaving. If you check out her blog, make sure you check out the comments by her readers.

What've I been doing? On Thursday I finally finished the third & final triple weave strip. Two of the layers are poly sewing thread, and the third layer is cotton. Last night I fed the 2nd & 3rd strips (the undyed strips) through the pleating machine, and today I dyed them. Some people ask how a pleating machine works. A pleating machine has a bunch of rollers with needles between the rollers. The needles are placed pointing into the machine, and the tips of the needles are curved, which keeps the needles in place among the rollers. Once the needles are in place in the machine, the eyes are threaded. Fabric is fed through the pleater (which is kind of like a pasta machine), onto the needles (since the pointy ends of the needles are in the inside of the machine), and then onto the thread. Once all of the fabric is fed throught the machine and onto the thread, the fabric is compressed & then dyed. Here are pictures of the curved needle & the threaded machine before the fabric is fed through it:

Here is the beginning of the fabric being fed through the machine, onto the needles, and then onto the pullup thread:

Here is all of the fabric fed through the machine:

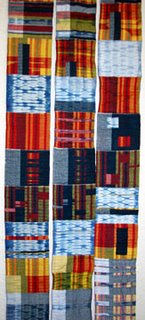

Here is a mockup (and a detail) of the three strips post dyeing and pre-stitching (The blue speckled areas are the cotton areas that were on the outside of the pleated bundle and thus were exposed to the dye.):

I'll use red thread to sew the strips together. The final size will be ~78" X 10". I have more warp, but I'm so over this project & I'm ready to move on. I also think this piece is a bit too busy. I'm very grateful to Peggy Osterkamp who has taught me multiple layer weaving. Peggy is an awesome teacher.

2 comments:

Glad to see that you have woven more of the triple weave! I think it will make a nice piece once the three strips are sewn together. It's not too busy IMHO - there is a nice movement of similar patterns from one strip to another - not matching but just enough "off" to give interest. Loom & Shuttle is always there for you!!

AHA! so now i finally know how a pleater works. Thanks for sharing

Post a Comment